HIGH HUMIDITY CAPACITY

It converts water into cold steam in the dimensions of 1 micrometer and distributes it to the environment through 600m³/hour fans.

FULL AUTOMATIC

Once the desired humidity range has been selected, the machine always starts and stops on its own to maintain this level.

AUTOMATICALLY TAKES WATER

After the water inlet connection of the device is made, the machine makes the water reinforcement itself. You do not need to add water manually.

PRECISION MEASUREMENT

With its built-in industrial sensor, it performs sensitive, ambient humidity and temperature measurements , works or stops accordingly.

HYGIENE & ERGONOMICS

WWith its wheel attachable feet, you can drive your machine to wherever you want and it is easy to clean thanks to its fiberglass structure.

MADE IN Turkey

Although it is not yet 100% national, we are preparing ourselves for the future by creating a detailed and sensitive infrastructure with confident steps.

TIMER FEATURE

You can operate by sensor or in timed mode! Ability to work with both sensor and timer feature in one machine!

PCB

The design and software of the electronic cards we use in our machines are made by us.

Sensor (Humidity & Temperature Sensor)

Humidity: %1.8 and Temperature: %0.2 with margin of accuracy, the design and software of the best sensor cards in the industry are made by us.

| Model | UNC-SS-1.4 | UNC-FB-7 | UNC-FB-14 | UNC-FB-21 | UNC-FB-28 |

|---|---|---|---|---|---|

| * The Area of Effect is directly related to your intended use, the space you use and the ceiling height! If you are going to use it for a mushroom house and there are powerful fans and high air flow inside, at least 2 devices may be required for an area of 100m². The situation can be different for systems such as tent systems and for humidifying places such as building basements. However, for places where there is no high air flow, 1 device can meet the humidity requirement up to 150m². Please consult us if you cannot decide where you will use and how much you need! | |||||

| Case Type | Stainless Steel (304) | Fiberglass | |||

| Capacity | 1.4 Liters/Hour | 7 Liters/Hour | 14 Liters/Hour | 21 Liters/Hour | 28 Liters/Hour |

| Voltage | 220V - 50Hz | 220V - 50Hz | |||

| Power (Watt) | 56 Watt | 295 Watt | 594 Watt | 880 Watt | 1166 Watt |

| Current | 1.5 A | 1.34 A | 2.7 A | 4 A | 5.3 A |

| Steam Flow Rate | 33 m³/hour | 295 m³/hour | 589 m³/hour | 884 m³/hour | 1178 m³/hour |

| Impact Area * | 16 m² | 50 m² | 100 m² | 150 m² | 200 m² |

| Humidity Outlet Chimneys | 5 mm x 130mm | 110 mm x 1 | 90 mm x 2 | 70 mm x 3 | 70 mm x 3 |

| Working Range (Outside Temperature) | 5℃~40℃ | 5℃~40℃ | |||

| Net Weight | 5.5 Kg | 15 Kg | 17 Kg | 19 Kg | 21 Kg |

| Packaged Weight | 6.9 Kg | 24 Kg | 26 Kg | 28 Kg | 30 Kg |

| Machine Dimension(Lng.)x(Hgt.)x(Wth.) | 15x20x15cm | 63.5x43.5x42cm | |||

| Packaged Dimensions | 32x32x26cm | 66x46x44cm | |||

| Maintenance Hour | 5000 Hours | 5000 Hours | |||

| Humidity & Temperature Control | Available | Available | |||

| Timer Feature | Available | Available | |||

| FOB Price (Exclude shipping fee.) | USD - | USD 700$ | USD 870$ | USD 1.090$ | USD 1.300$ |

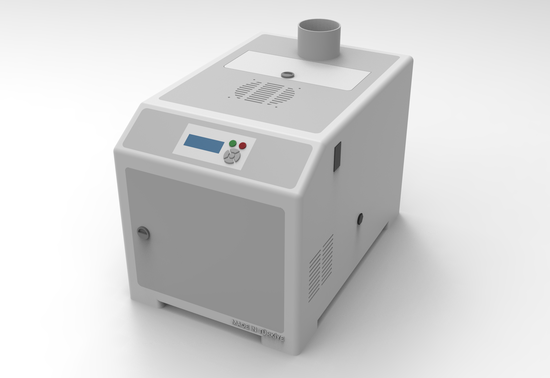

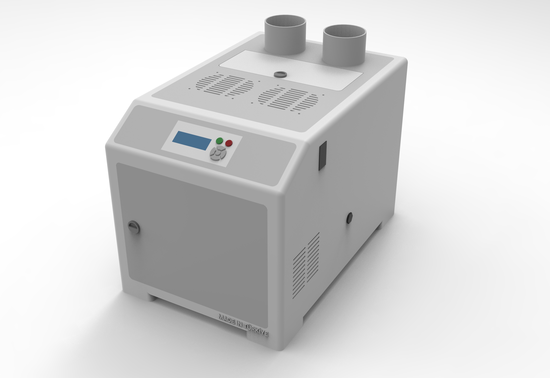

Fiberglass Product Photos

Videos

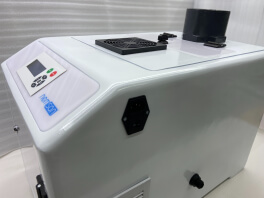

UNC-SS-1.4 - 1.4 Liter/Hour capacity Stainless Steel outer case ultrasonic humidifier photos

Share your questions, problems and thoughts with us. If you wish, we can call you immediately. Or you can chat with us instantly from the live support section in the lower right corner.